Meter Tails

Electrical Safety First has been raising awareness of some of the safety concerns regarding the installation of smart electricity meters.

We believe that the tightness of meter tail connections within a consumer unit should be routinely checked as part of the smart meter installation process – something which energy companies and meter operators do not currently do.

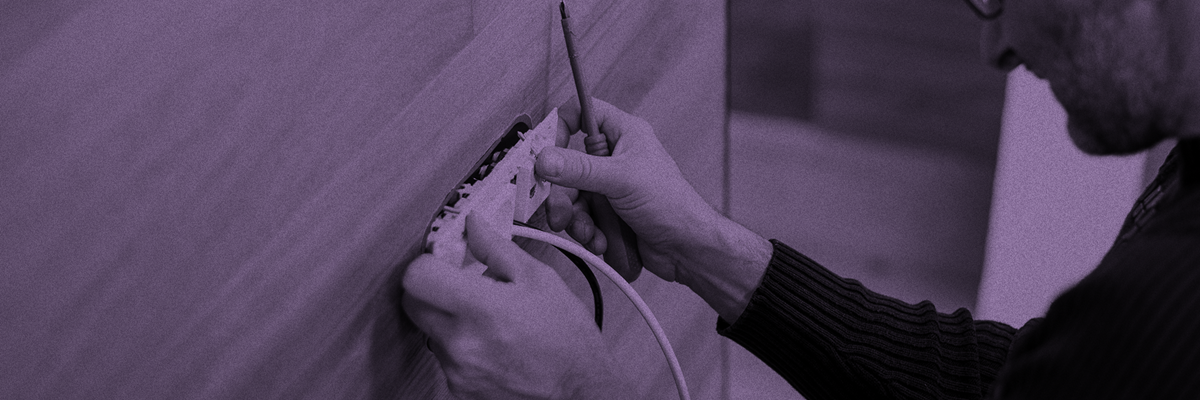

Removing the old meter and installing the smart meter may mean that the meter tails to the consumer unit are disturbed such that the connections within the consumer unit are loosened. This could result in the meter tails pulling out of their connection causing a risk of electric shock, loss of supply, or to creating a high resistance connection that could lead to an increased risk of fire.

Evidence from a report produced by East Sussex Fire and Rescue Services, and from other reported fire incidents, indicates that many fires occur within the consumer unit, some of which were as a result of a high resistance connection.

Investigation

To support our concerns and the anecdotal evidence, we commissioned an independent laboratory to simulate changing an electricity meter to determine what effect disturbing the meter tails would have on the connections to the incoming terminals of the isolator within a consumer unit, positioned in a typical meter/consumer unit arrangement.

The investigation included a comparison between a traditional 7-strand conductor and a 19-strand conductor, as the latter is more flexible and has been adopted by several meter operators as their preferred type of conductor for connecting the meter to the cut-out and/or to a consumer’s isolating switch, due to its claimed improved connection properties.

It also looked at whether different cable end preparation by flattening or twisting the conductor prior to connection was also included.

A selection of six consumer unit isolator switches and a combination of conductors sized 16 mm2 (7-strand) and 25 mm2 (7-strand and 19-strand) – that’s 18 connections – were subjected to the following test methodology:

- Test 1 –tighten to manufacturer’s stated torque or, where none is stated, as tabulated in BS EN 60947-1, and recheck torque after 24 hours.

- Test 2 – simulate foreseeable movement of meter tails using a ‘flexion’ test, as described in BS EN 60947-1

- Test 3 – apply a tighter twist to the strands prior to connection and apply procedures A and B below.

- Test 4 – flatten the conductor (with pliers by hand) such that there is minimal displacement of conductors prior to connection and apply procedures A and B below.

- Procedure A – Apply a pull-out test as described in clause 8.2.4.4 in BS EN 60947-1 – record the pulling force.

- Procedure B – measure and record the movement, if any, of the terminal screw to reach the specified torque.

Results

|

Test 1 |

Test 2 |

Test 3 * |

Test 4 ** |

|

|

Connections pulled out |

3 |

9 |

1 |

1 |

|

Connections requiring retightening to original torque |

7 out of remaining 15 |

10 out of remaining 11 |

10 out of remaining 15 |

4 out of remaining 14 |

*unable to terminate two conductors following preparation procedure

** unable to terminate three conductors following preparation procedure

The results of the investigation confirm our view that the tightness of meter tail connections in consumer units should be checked after changing a smart meter (or other electricity meter), where there is a risk of the meter tails being disturbed.